销售热线

TNGO, a machine builder that has supplied luminance inspection machines to major Korean LED production facilities, has integrated the Cognex DataMan® 100X and 100S, as well as the In-Sight® Micro 1110 into their LED luminance inspection machine to create an automated part history management system with a track and trace system. This successful system has now been installed in nine LED production lines.

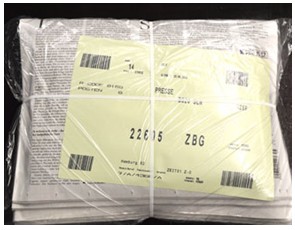

TNGO’s LED-bar luminance defective inspection moves along 30 meters with 5 stages of testing. Each plate has 16 bars and each bar and plate has unique barcodes to verity that the test is being properly performed by each stage.

In the LED-bar luminance test, in particular, products move rapidly, and diffused reflection is severe because of the intense vibration. Because of the environment, a barcode reader which guarantees high read rates even under variable work conditions was required by TNGO. In addition, the bars are close together so TNGO needed a compact barcode reader that could be installed in a very small place and could tolerate a small field of view in which to search for codes.

The Cognex DataMan 100 series is an ultra-small, fixed-mount reader which integrates lighting, camera, processor, and communication functions. This product is perfect for production facilities which require the greatest performance in a very limited space. It was the first choice for starting TNGO’s parts history management system. The DataMan 100X presents the highest read rates under any circumstances such as code deformation. DataMan 100X offers the powerful 2-D decoding software, IDMax® ,and offers superior performance capable of handling all codes from 1-D/2-D barcodes to the most difficult Direct Part Marked (DPM) codes. This model has exhibited the best performance in reading the end user’s ECC 0 2-D Data Matrix code (17x17).

Mr. Kim Jae-gwang of IDINTECH, a Cognex ASP (Automated Solutions Provider), said ,“The DataMan 100X is a high-performance, ultra-small product with a capacity of handling 60 frames per second and up to 45 decodes per second. Because it enables USB and RS-232 communications as well as a PoE (Power of Ethernet) connection, it is very convenient in system integration.” He also said, “While other companies still use a 1-D scanner for LED history management system, TNGO has adopted the DataMan high-performance 2-D reader in consideration of compatibility and extendibility in the future, which has made it possible to provide better solutions.”

Meanwhile, TNGO has focused on enhancing the productivity of the history management system by integrating the DataMan reader with an In-Sight Micro 1110 ID vision system. The combination of Cognex products has made it possible to read four LED-bar barcodes at the same time it is being inspected using the In-Sight Micro at the final stage of the luminance. This has maximized the speed and efficiency of the entire process.

The In-Sight Micro ID reader, which features high-tech OCR/OCV tools and 1-D/2-D code reading and identification software, enables character and barcode reading at the same time.

Jae-gwang said again, “Unlike the manually operated conventional history management system, the Cognex vision solution-based automated history management system has enhanced work productivity up to three times.” He added, “Because additional facility investments continue thanks to high demand for LED products, it appears that the demand for a history management system would increase accordingly.”

About TNGOTNGO has accumulated great knowledge and technology in the automation of manufacturing facilities in the semiconductor and display industries, the automation of various testing and inspection facilities and manufacturing equipment & system integration solutions. The company now develops and provides LED module in-line automated inspection equipment, high-temperature lighting inspection equipment, low-current lighting inspection equipment, and manual LED module inspection systems with diverse solutions in automation. The company started under the name of Ai-OS ENG in 1992 and was renamed to TNGO in 2004. For more information, visit their website (http://www.tngo.co.kr).

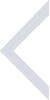

通常ControlLogix、CompactLogix连接Modbus都是使用MVI56E-MCM、MVI69-MCM,价格高达万元以上,而且还需要进行编程,新手用起来有一定的难度,且耗费工程技术人

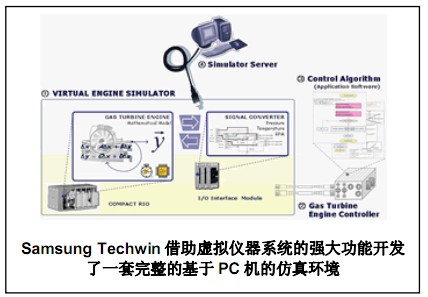

“NI VeriStand与NI PXI平台的结合满足了用户对I/O、计算能力、信号仿真和数据分析等功能的需求,而且是完全开放和模块化的。”–Enrico Corti, Alma Automoti

应用领域 能源/电力 使用的产品 CompactRIO, LabVIEW, LabVIEW FPGA, LabVIEW Real-Time 挑战 开发一个引擎仿真测试系统以提高Samsung Tec

要解决的问题: 代替陈旧的激光扫描技术,在高速报纸生产线上进行条码读取,这些条码的高度和位置各不相同且位于塑料下面。解决方案: DataMan 500 条码读码器提供 100 % 的可靠性。优势:

标签:NB-IOT今年6月16日,NB-IoT技术协议获得了3GPP 无线接入网(RAN)技术规范组会议通过。从立项到协议冻结仅用时不到8个月,成为史上建立最快的3GPP标准之一。在9月完成性能标准

'我作为一个狂热的LabVIEW开发者已经有10年,这10年中,我发现没有任何一款其它的应用程序开发环境(ADE)能够提供像LabVIEW一样快捷、灵活的软件开发和调试体验。另外,LabVIEW提供

概述最近在做一个消防车水力性能检测系统的项目,这个项目的业务逻辑复杂,要存储的信息多,在这个消防系统几乎每个界面都会使用存储的信息,这些信息是通过access关系数据库来存储的。紫金桥组态软件里的

以康耐视 DataMan 100 工业 ID 读码器为基础的 White Reader 尺寸小巧,但却具有无与伦比的数据矩阵代码读取性能。该读码器配备专为外科器械开发的专利三色照明系统,能够有效读