销售热线

要解决的问题: 代替陈旧的激光扫描技术,在高速报纸生产线上进行条码读取,这些条码的高度和位置各不相同且位于塑料下面。 解决方案: DataMan® 500 条码读码器提供 100 % 的可靠性。 优势: DataMan 条码读码器具有无与伦比的读取速率,能够带来理想的追踪效果。DataMan 读码器不带有任何活动部件,这大大降低了 Axel Springer 过去为维修激光扫描仪花费的维护费用。

Speed is essential in the world of the printed word. Newspapers must reach their readers reliably, day in day out. Hamburg-Ahrensburg offset printers are supported by a DataMan® 500 from Cognex to guarantee smooth and accurate logistics. The image-based barcode reader, which has been integrated into the system by bci GmbH, lowered investment, maintenance and repair costs.

Hundreds of thousands of newspapers are rushing over the heads of the employees at great speed. Hot off the press, the headlines, news reports and latest stories are on their way to their readers, clamped firmly along the fold to the aerial conveyor belts. Speed is everything. News is only news if it is fresh, not if it is old hat. These are the demands made on the technology at Hamburg-Ahrensburg offset printers. Axel Springer has been printing newspapers for northern Germany here since 1983, in addition to publications on behalf of other publishers. This is where the words of Das Bild, the Hamburger Abendblatt, Die Zeit and many other print papers took physical form and were made visible for the readers. Barcodes are used to pack the newspapers into bundles to make sure they not only arrived quickly but also at the right address. For three decades the barcodes were read using a laser scanner with a tilting mirror, but recently this mature technology was replaced by the next generation of barcode readers: Cognex image-based logistics barcode readers, which ensure high precision identification. The intelligent DataMan 500, integrated by the bci GmbH and operational technology staff into the component systems of Axel Springer AG, reads the barcode codes at lightning speed and with 100 percent reliability.

Reflections from the creases

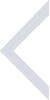

Anyone who has ever passed a newspaper kiosk early in the morning will be familiar with the piles of newspapers wrapped in plastic foil. The machines at the Hamburg-Ahrensburg offset printing press stack newspapers in piles up to 10 inches high (depending on the order quantity), put a covering sheet on top with 1-D codes, wrap the pile in transparent plastic and finally tie it up cross-wise with plastic packaging straps. The DataMan 500 reads the codes immediately after this step as the package passes along the conveyor belt. If there is one combination that you do not want from the point of view of an optical sensor, it is codes on paper with a variety of colors plus creased, highly reflective sheeting. This was a real challenge for the bci GmbH experts and was the key factor in the decision to choose the Cognex DataMan 500 barcode reader.

It was clear when the Axel Springer AG project started in November 2011 that the laser scanner was coming to the end of its operational life. Wear and tear on the tilting mirror and other movable parts was too great and the resulting maintenance and follow-up costs were too high. It was also becoming increasingly difficult to get hold of replacement parts for the aging equipment and the read failure rate was no longer acceptable. A decision was made to replace it with modern, image-based ID reading equipment from Cognex, which are designed with no moving parts that wear out.

Traceability

The high performance DataMan 500 made it possible for bci GmbH to achieve 100 percent reliability in reading the barcodes after a test phase of just four weeks. And that was for newspaper bundles ranging in height from 0.5 to 10 inches and variations in the position of the code over a range of 15 inches plus. That was no problem for the DataMan 500 because of its depth of field capabilities. To make maximum use of the reader’s potential, bci prioritized customer-specific programming. These complex challenges were overcome rapidly in a number of test runs.

Filtered light

The DataMan 500 only needs one master setting to manage the incoming packs of highly reflective newspapers with their different heights and varying positions. The intelligent DataMan utilizes an HPIA (high-powered illumination accessory). Both the DataMan 500 lens and the additional light source are fitted with polarizing filters, which effectively reduce the cross-fade produced by the packaging foil.

Because the pilot project is running so reliably, Hamburg-Ahrensburg offset printers are planning to replace the aging laser scanners throughout the system with Cognex barcode reading equipment in the medium term. The reasons for doing this are the lower investment costs and the reduction in maintenance costs.

With an eye on the future, the flexibility of DataMan 500 is also a significant plus for Axel Springer, as it will be easy to reprogram the Cognex image-based barcode reading equipment if they switch to using 2-D codes in the near future. Last but not least, the DataMan 500 even consumes significantly less electricity than the laser scanner.

Speed is essential in the world of the printed word. Newspapers must reach their readers reliably, day in day out. Hamburg-Ahrensburg offset printers are supported by a DataMan® 500 from Cognex to guarantee smooth and accurate logistics. The image-based barcode reader, which has been integrated into the system by bci GmbH, lowered investment, maintenance and repair costs.

Hundreds of thousands of newspapers are rushing over the heads of the employees at great speed. Hot off the press, the headlines, news reports and latest stories are on their way to their readers, clamped firmly along the fold to the aerial conveyor belts. Speed is everything. News is only news if it is fresh, not if it is old hat. These are the demands made on the technology at Hamburg-Ahrensburg offset printers. Axel Springer has been printing newspapers for northern Germany here since 1983, in addition to publications on behalf of other publishers. This is where the words of Das Bild, the Hamburger Abendblatt, Die Zeit and many other print papers took physical form and were made visible for the readers. Barcodes are used to pack the newspapers into bundles to make sure they not only arrived quickly but also at the right address. For three decades the barcodes were read using a laser scanner with a tilting mirror, but recently this mature technology was replaced by the next generation of barcode readers: Cognex image-based logistics barcode readers, which ensure high precision identification. The intelligent DataMan 500, integrated by the bci GmbH and operational technology staff into the component systems of Axel Springer AG, reads the barcode codes at lightning speed and with 100 percent reliability.

Reflections from the creases

Anyone who has ever passed a newspaper kiosk early in the morning will be familiar with the piles of newspapers wrapped in plastic foil. The machines at the Hamburg-Ahrensburg offset printing press stack newspapers in piles up to 10 inches high (depending on the order quantity), put a covering sheet on top with 1-D codes, wrap the pile in transparent plastic and finally tie it up cross-wise with plastic packaging straps. The DataMan 500 reads the codes immediately after this step as the package passes along the conveyor belt. If there is one combination that you do not want from the point of view of an optical sensor, it is codes on paper with a variety of colors plus creased, highly reflective sheeting. This was a real challenge for the bci GmbH experts and was the key factor in the decision to choose the Cognex DataMan 500 barcode reader.

It was clear when the Axel Springer AG project started in November 2011 that the laser scanner was coming to the end of its operational life. Wear and tear on the tilting mirror and other movable parts was too great and the resulting maintenance and follow-up costs were too high. It was also becoming increasingly difficult to get hold of replacement parts for the aging equipment and the read failure rate was no longer acceptable. A decision was made to replace it with modern, image-based ID reading equipment from Cognex, which are designed with no moving parts that wear out.

Traceability

The high performance DataMan 500 made it possible for bci GmbH to achieve 100 percent reliability in reading the barcodes after a test phase of just four weeks. And that was for newspaper bundles ranging in height from 0.5 to 10 inches and variations in the position of the code over a range of 15 inches plus. That was no problem for the DataMan 500 because of its depth of field capabilities. To make maximum use of the reader’s potential, bci prioritized customer-specific programming. These complex challenges were overcome rapidly in a number of test runs.

Filtered light

The DataMan 500 only needs one master setting to manage the incoming packs of highly reflective newspapers with their different heights and varying positions. The intelligent DataMan utilizes an HPIA (high-powered illumination accessory). Both the DataMan 500 lens and the additional light source are fitted with polarizing filters, which effectively reduce the cross-fade produced by the packaging foil.

Because the pilot project is running so reliably, Hamburg-Ahrensburg offset printers are planning to replace the aging laser scanners throughout the system with Cognex barcode reading equipment in the medium term. The reasons for doing this are the lower investment costs and the reduction in maintenance costs.

With an eye on the future, the flexibility of DataMan 500 is also a significant plus for Axel Springer, as it will be easy to reprogram the Cognex image-based barcode reading equipment if they switch to using 2-D codes in the near future. Last but not least, the DataMan 500 even consumes significantly less electricity than the laser scanner.

工业生产污水在线处理监测方案一、项目背景 随着经济的发展,我国的污水排放量已越来越大,已造成地表水的严重污染,环境质量呈现不断恶化趋势,但目前全国各地对污染源和排污河渠的水质监测仍停留在手工监测阶段

在提高生产质量和生产效率的同时实施工业 4.0 和物联网(IoT)方案,这一需求带来了工厂数据量的大幅增长。基于 PC 的控制技术性能优异,并能够与 IT 领域深度融合,为处理这些庞大的数据量提供

使用产品: MOXA ED6008 国家及地区: 中国大陆 其他应用: 原煤生产运输智能集中监控系統客户简介 张集煤矿坐落于中国大陆安徽省鳯台市及淮南市的华东经济特区内,是中国大陆95国家建设规划之

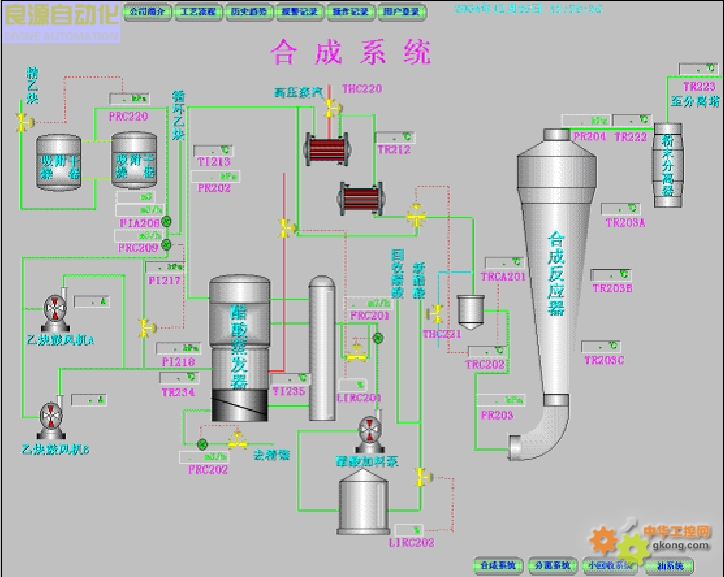

一、系统描述醋酸乙烯是一种十分重要的工业原料,其市场非常广阔.它的生产过程主要分为两个大的过程:合成和精馏.前者是发生化学反映生成醋酸乙烯的过程,后者则是将生成的醋酸乙烯通过学,物理过程来进行提纯.

【行业概述】污水处理是目前我国大力开展环境保护治理工作的一项重要内容,对保护我国的生态环境起着非常重要的作用。要使污水处理的水质、水量达到国家排放标准,提高污水处理能力,增加效益,污水处理厂在污水处

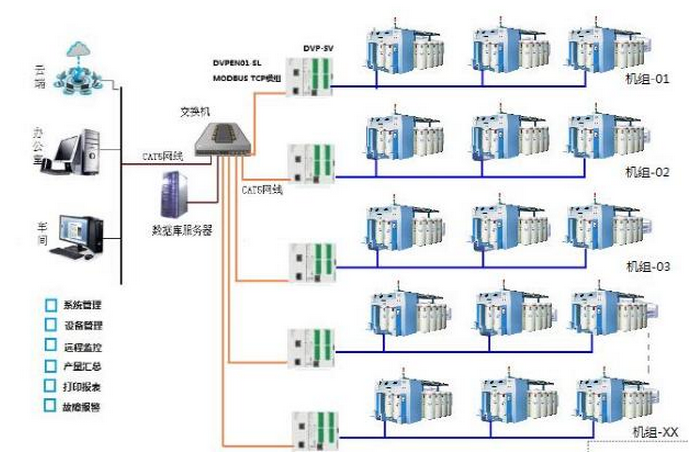

随着PLC、变频器、伺服系统等自动化技术的大范围推广和普及应用,纺织机械的自动化水平已经取得长足发展。但由于这些自动化技术的应用多侧重于单台设备纺织工艺自动化水平的提升,因此也造成了大量信息孤岛的

使用产品:VPort 354项目介绍对于危险行业,如FPSO(浮式生产,储存和卸载),视频监控是安全控制和监测的关键。Moxa与一个控制和仪器仪表供应商合作为石油和天然气工业提供离岸FSPO平台的关

基本介绍: 滴灌带的生产,首先是塑胶带的挤出机,然后是塑胶带的打孔设备,这里着重介绍塑胶带的打扎部分。当挤出机将塑胶带挤出后,经过变频器的调速牵引,做一个速度控制。在主速牵引时进行同速的打孔。在同